Rail Type Mechanical Opening &Closing Door Foaming Line

It is a kind of door foaming line used to manufacture refrigerator or freezer door. The foaming line is a rotary (hub ty

Send your inquiryDESCRIPTION

Basic Info.

| Model NO. | SN-017 |

| Rhythm | Flow Production Line |

| Production Scope | Product Line |

| After-sales Service | After Sales Service |

| Cycle Time | 120s |

| Pneumatic | SMC |

| PLC | Siemens |

| Air Supply Pressure | 0.6MPa |

| Electricity Capacity | 120kw |

| Transport Package | Export Package |

| Trademark | Shangnuo |

| Origin | Chuzhou, Anhui, China |

| HS Code | 84807190 |

Product Description

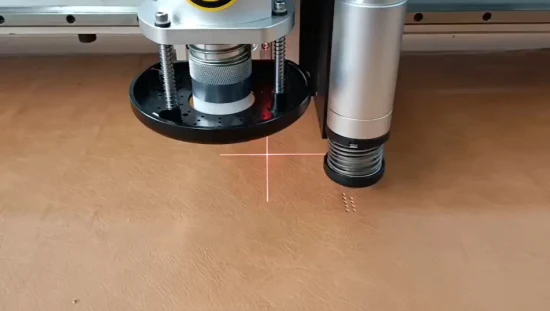

The foaming line is a rotary (hub type) seven (eight) station door body foaming equipment, mainly used for refrigerator (cabinet) door body foaming. It is composed of the main frame, rotating frame, foaming mold frame, hydraulic drive, positioning, mold opening and closing system, loading and unloading system, variety identification system, and supporting hydraulic system, electronic control system and other parts.

The foaming line is composed of manual lifting and releasing work pieces, automatic backstroke filling, rotary mold closing, cylinder mold locking, completion of curing, cylinder locking, mold opening when the lower mold frame is lowered to the original position, and operation personnel can take out the door body finished products and other processes.

Water heating is adopted for each template of fixture. Mould clamping is safe and reliable, mould changing is convenient and quick, suitable for flexible production of various kinds. The production line has the characteristics of small floor space, compact structure and easy operation.

General Technical Data

Outer dimension: 6000×5500×4600mm

Working stations: 7 (8)

Fixture size(L X W) : 2000mm×900mm

Mould close height: 200mm

Cycle time: 46s (not including the operation time)

Foaming agent: POL(Cycle pentane or141b)+ISO

Injection mode: open injection automatically

Heating mode: water heating by mould temp controller

Power consumption: ~65KW(3890V,50Hz)

Anhui Shangnuojieshun Intelligent Technology Co., Ltd. is located in the Economic Development Zone of Quanjiao County, Anhui Province. We now have more than 70 employees, among them 40% are engineers and technicians. We aims to become an advanced home appliance equipment supplier in the world. Our mission is to "provide advanced equipment for customer product innovation, process optimization and production efficiency improvement".

Our main products include: Sheet metal automation equipment, automatic foaming equipment, a full set of intelligent assembly equipment for cold chain products, various intelligent bonding and pressing equipment, etc.

For more than 10 years, we have served high-end customers at home and abroad with a number of patented automation technologies and won their recognition and recommendation. Our customers include CEI, Haier, Panasonic, Meiling, Sharp, Hisense, Midea, Whirlpool, Siemens, TCL, GREE, Konka, Skyworth and other famous companies.

Related Products