Automatic Die Cutting PU Foam Cutting Machine Price

Automatic Die Cutting PU Foam Cutting Machine Price Machine Introduction:1. Integrated Welding Steel Constructed TableTh

Send your inquiryDESCRIPTION

Basic Info.

| Power Source | Electric |

| Layout | Vertical |

| Servo Motor | Delta, Panasonic, Yaskawa, FUJI Can Be Selected. |

| Working Voltage | 110V/220V/380V; 50Hz/60Hz |

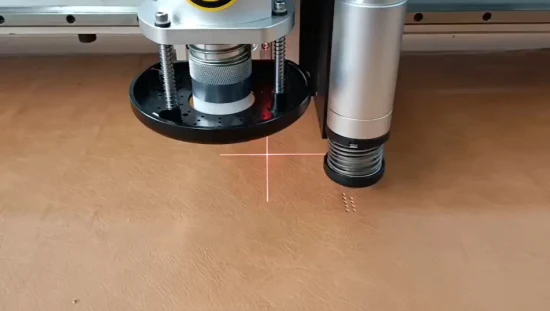

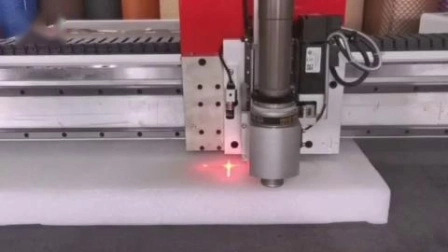

| Location Mode | Infrared Laser Lamp |

| Driving Method | Belt or Racking Can Be Selected |

| Cetificate | CE/SGS; ISO9001/ISO14001/ISO18001 |

| Safety Device | Mechanical Anti-Collision Device or Fwd Ds or Scra |

| Power of Suction Fan | 9kw |

| Cutting Thickness | 0.1-50mm |

| Material Fixed Type | VAC-Sorb (Vacuum Absorption) |

| Cutting Accuracy | Error 0.1mm |

| Machine Size | 3410mm * 2180mm *1370mm |

| Cutting Speed | Max. 140m/Min (Per Material) |

| Working Plate | 2500 * 1600mm |

| Transport Package | Wooden Box |

| Specification | KJZD-1625 |

| Trademark | kangjia |

| Origin | China |

| HS Code | 8453100000 |

| Production Capacity | 100 / Month |

Product Description

Automatic Die Cutting PU Foam Cutting Machine Price

Machine Introduction:1. Integrated Welding Steel Constructed TableThe machine is built with a durable, stable, 6mm all-steel tube frame which significantly reduces vibration and gives the operator tight control for precise cutting.2. Conveyor SystemDesigned for easy loading and unloading of materials, the Conveyor System provides operators a fast advance control of material and serves as a vacuum cutting surface ideal for roll materials.3. Digital Servo Drive SystemBrushless AC Servo Motors, guide rail, rack and pinion are integrated into the machine providing both velocity and torque with uncompromised accuracy for cutting applications. 4. Safety DeviceEquipped with infrared automatic sensor device and four emergency stop buttons, the Safety Device provides a safe working environment.5. Accurate and Stable Working TableThe cutting table is built with 7 series aviation aluminum which contains a honeycomb structure inside, sturdy, high-precision, non-deformable, stable for long-term running.6. Regional Vacuum Adsorption SystemThe vacuum adsorption area can be selected according to the size of the materials. By using individual vacuum controls for each area, the vacuum system greatly reduces the need for masking open areas of the table.7. Motion Control systemThe motion control system consists of a motion controller and a LCD touch control panel. It can make the cutting process smooth, efficient, perfect. And the control panel is quite easy to operate with English interface.8. Cutting HeadsThe machine can be equipped with one cutting head or multiple cutting heads. Different cutting tools can be changed and mounted on the cutting heads for different cutting needs.

Technical Data:

| Model | 1625/1630/1830/2030, can be customized. |

| Working area | 1600*2500mm /1600*3000mm/1800*3000mm/2000*3000mm |

| Rated power | 7-11KW |

| Fixed mode | Flat table /auto feeding table optional , table structure: whole welding process |

| Multifunctional heads optonal | Vibration knife (oscillatory knife) |

| Circular knife (round knife / rotary knife) | |

| Oblique knife (V-cut) | |

| Marking pen | |

| Punching roller (round punching/v-punching/optional) | |

| Milling knife | |

| Drag knife | |

| Pneumatic knife | |

| Projector and camera optional | |

| Safety device | Using infrared sensors, mechanical safty device, Intelligent anti-collision device responsive, safe and reliable. |

| Material feeding type | Auto feeding or manual feeding |

| Material fixed type | Vac-sorb (vacuum absorption), suction fan power: 2.2kw / 7.5kw / 9kw |

| Translational velocity | 800-1500mm/s |

| Cutting speed | Max. 1500mm/s (according to different cutting materials) |

| Cutting thickess | ≤60mm (according to different cutting materials) |

| Cutting material | Fabric, all kinds of clothing flexible material, Sponge leather, PVC, soft glass, Silicon, rubber, cardboard etc. |

| Repated accuracy | ≤0.1mm |

| Cutting type | Mechanical vibration physical cutting |

| Transmission / driving system | Motor brand Panasonic, YASKAWA, Fuji, Delta |

| Transmission type / Guide rail | Digital servo motor, linear guide, synchronous belt, rack/spline, ball screw |

| Instruction system | HP-GL compatible format |

| Control system | LCD touch screem ( custom made) |

| Voltage | 110V/220V / 380V±10%; 50HZ, 60HZ |

| Other configuration | Germany imported conveyor belt, vacuum table, Taiwan Hiwin rail, vacuum pump |

Related Products:Products Advantages:1. Time Saving: The machine cuts by vibration knife. It's possible to finish cutting 3 pieces of 4D or 5D car mats within 3 minutes, much faster than cutting by hand. It guarantees fast output of customized car mats. 2. Material Saving: Pattern nesting can be done and checked carefully before cutting, avoiding hiden lost during careless cutting by workers. It can save at least 5% materials than manual cutting. 3. Storage Room Saving: Cut whatever you want, whenever you need. No need to have a large storage room for a large quantity of ready car mats. 4. Flexibility: Each customer can pick up the materials, patterns they like to make the special car mats for their special cars, expending a large automotive beauty industry at your end!Company show:Jinan Kangjia CNC Equipment Co., Ltd is located in Jinan city of China and built in year 2016. It is a comprehensive service company specializing in the production, sales and technical service of knife cutting machine and laser cutting machine. It covers multiple fields and industries, such as automotive decoration, toys, garment, leather product, furniture etc. Its R&D level and production capacity has always been in the leading position in the same industry. The factory covers 10000 square meters, with 150 staffs in total. The production capacity is about 100 unit / month. Our team:Certificate:Our service:Before sales:

- Reply you within 24 hrs for your inquiry or question.

- Learn your detail requirements and what material you will cut. Then recommend the good solution that suit for you.

- Sign sales contract and receive the deposit.

- Multiple payment way can be selected, T/T, L/C, Western Union etc..

- Arrange production.

- Track the production schedule.

- Debug machine.

- Pack with wooden box and shipping.

FAQ:1. How do I choose the right machine for me?You can tell us your working material, detail work by picture or video so that we can judge whether our machine can meet your need or not. Then we can give you the best model depends on our experience.2. Is it easy to operate?Yes, it's very convenient. It supports multiple formats. In addition, our professional technical support personnel. At any time

3. Is the machine safe to operate?Our machines are equipped with multiple protection measures to ensure that the operator's

4. What's the guarantee, in case the machine breaks down? The machine has one year guarantee. If it breaks down, generally speaking, our technician will figure out what the problem may be, according to client s feedback. Parts except for consumable parts will be replaced for free if the problems are caused by quality problem under "normal use". .

5. How's the payment? TT,PAYPAL,Western Union(WU),and so on

Related Products

-

![Construction Cellular Lightweight Mixing Concrete Block Brick Making Machinery Foam Cement Foaming Generator Machine]()

Construction Cellular Lightweight Mixing Concrete Block Brick Making Machinery Foam Cement Foaming Generator Machine

-

![ESD Effect Foam Packing Box IXPE Sponge Foam Sheet for Shape Cutting Ln]()

ESD Effect Foam Packing Box IXPE Sponge Foam Sheet for Shape Cutting Ln

-

![China CNC Equipment Flexible Material Household PU Leather, Foam XPE Cutting Machine with Auto Feeding]()

China CNC Equipment Flexible Material Household PU Leather, Foam XPE Cutting Machine with Auto Feeding

-

![Continuous Filling Puf Foaming Pert Flexible Insulation Pipe Extruder Machinery for District Heating Pipe]()

Continuous Filling Puf Foaming Pert Flexible Insulation Pipe Extruder Machinery for District Heating Pipe